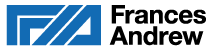

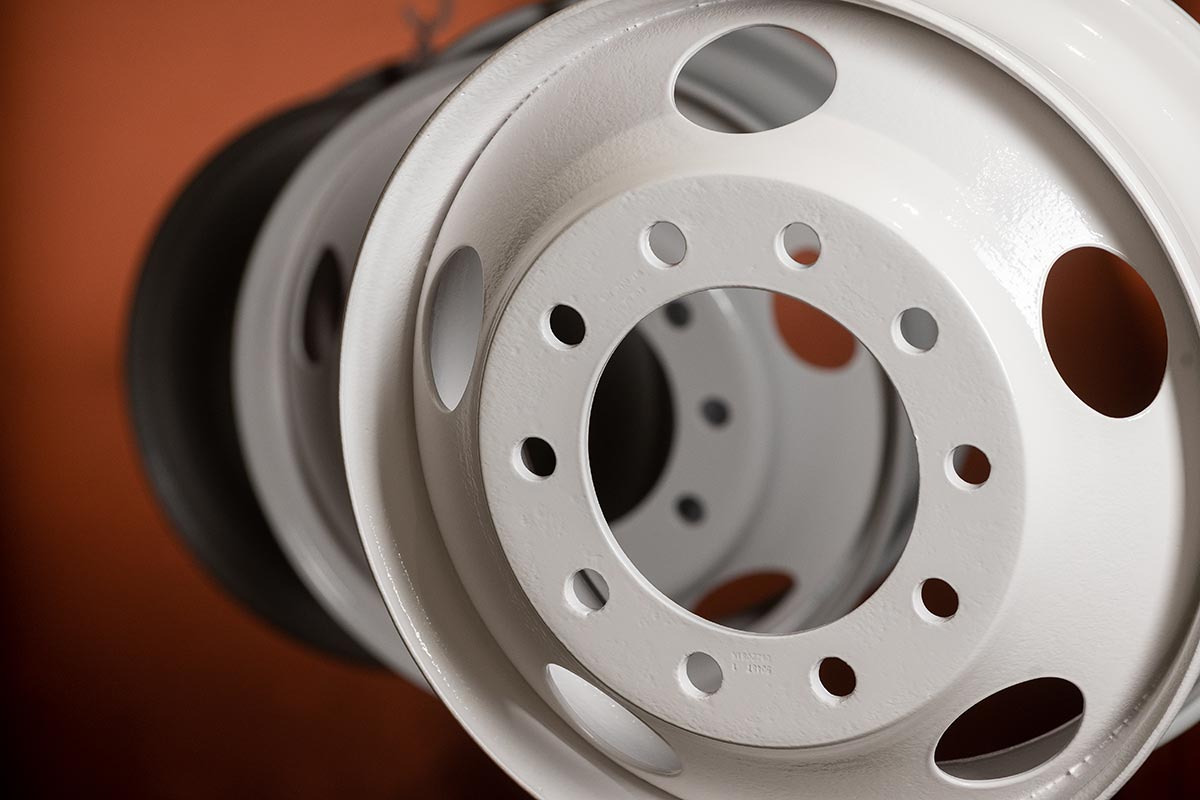

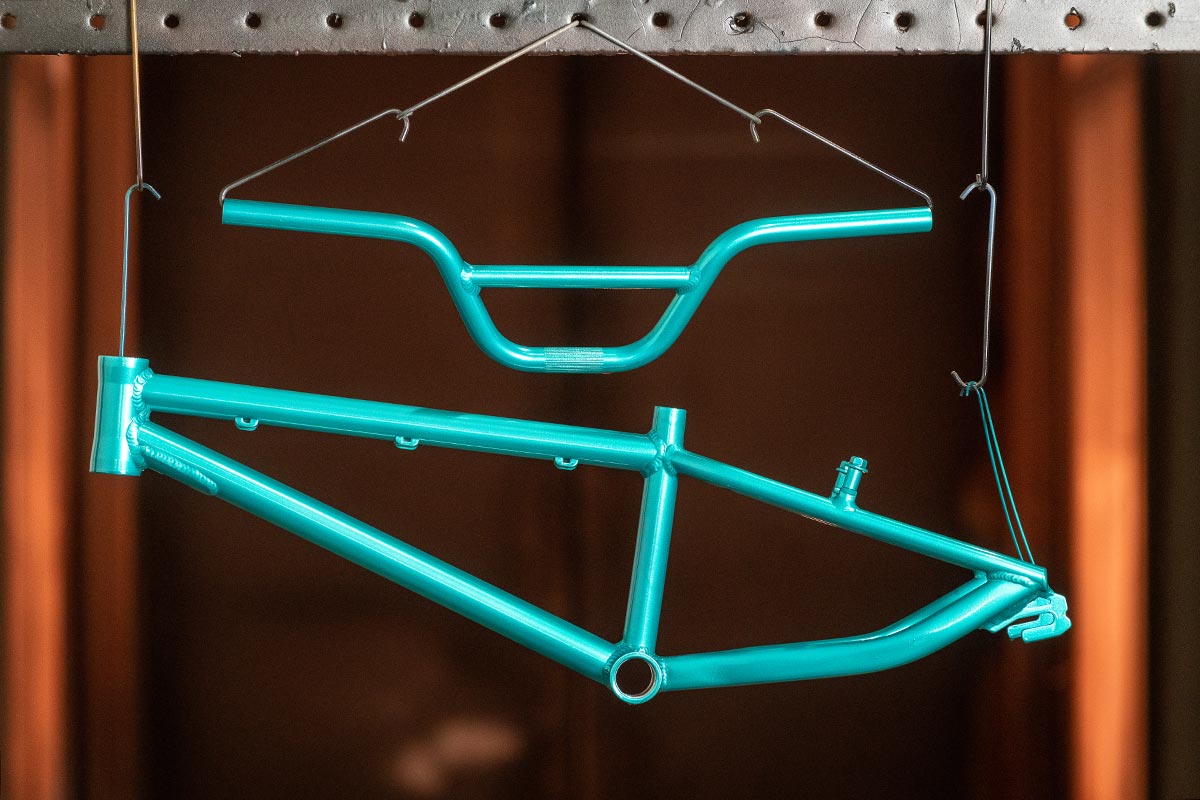

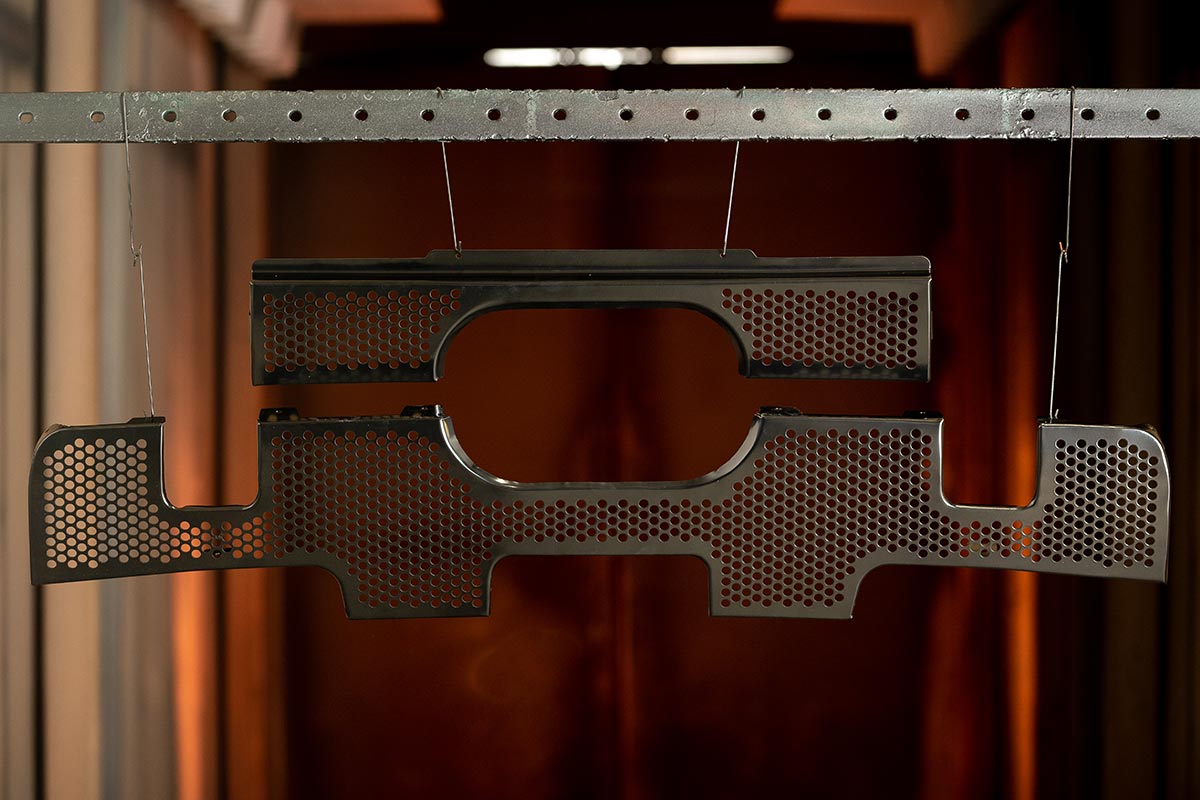

Powder Coating

Let’s get baked! Our paint shop boasts over 30 years of experience in delivering a safe and superior alternative to conventional painting. It’s a high quality, rust-free finish that is scratch and chip resistant—and can last over 20 years.

All items brought in for powder coating must be sandblasted before we can start the painting process. It is our preference that this is done before bringing items into our shop, although for a fee we can take care of this process for you.

Frances Andrew uses Tiger Drylac for our standard 26 colours and Prismatic Powders Canada for custom colours.